Understanding pallet wrapping machine repair for managers

Wiki Article

Discover the Crucial Benefits of Making Use Of a Pallet Wrapping Maker in Your Storehouse Procedures

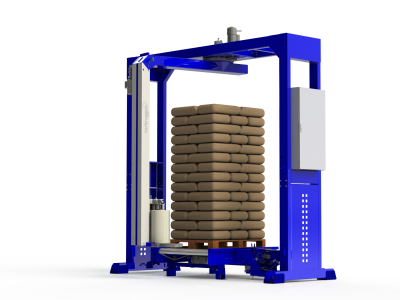

In modern warehouse procedures, the adoption of pallet Wrapping equipments is coming to be progressively crucial. These machines streamline the product packaging procedure, enhancing performance while substantially decreasing labor costs. They likewise assure constant Wrapping high quality, which is vital for item security during transportation. The benefits prolong beyond just these elements. There are extra advantages that can transform warehouse management, making it worthwhile to discover better.Boosted Efficiency in Packaging Workflow

In the domain name of logistics, efficiency stands as a vital purpose, and pallet Wrapping machines substantially contribute to achieving this objective. These equipments enhance the packaging process by automating the Wrapping of items, making sure that things are firmly packaged with minimal manual intervention. By decreasing the time invested in Wrapping, companies can optimize their process, allowing for quicker turn-around times and boosted throughput. Additionally, pallet Wrapping devices give consistent Tension and insurance coverage, improving the defense of products during transport. This integrity lessens the danger of product damage, which can bring about expensive hold-ups. Generally, the assimilation of pallet Wrapping devices into product packaging operations cultivates a more effective, dependable, and organized strategy to logistics monitoring.Substantial Labor Expense Cost Savings

While companies strive to reduce functional expenses, the adoption of pallet Wrapping machines can cause substantial labor cost financial savings. By automating the Wrapping process, these makers minimize the need for manual work, permitting workers to concentrate on more vital tasks. With the capability to cover pallets promptly and constantly, fewer workers are needed to complete packaging procedures, leading to reduced pay-roll expenditures. Furthermore, the machines improve productivity as they can run continuously, lowering downtime connected with manual Wrapping. pallet wrapping machine repair. This performance equates to quicker turn-around times and improved overall process. In addition, training staff members to run these equipments typically calls for much less time contrasted to training for manual Wrapping methods, further adding to decreased labor costs in warehouse proceduresEnhanced Product Defense During Transit

Reliable and constant Wrapping Quality

Pallet Wrapping machines provide regular and trustworthy Wrapping quality, ensuring that every pallet is wrapped uniformly despite operator experience. This harmony decreases the risk of damages during transportation, as effectively wrapped pallets maintain their integrity. The machines use an excellent quantity of stretch film, reducing waste and guaranteeing that the load is secured successfully. Unlike guidebook Wrapping, which can differ significantly based on the worker's strategy, an automated procedure guarantees that each why not check here pallet gets the very same level of protection. This integrity not only enhances the security of items but additionally improves operations, permitting an extra reliable process. Eventually, the constant Wrapping top quality supplied by these machines causes boosted client satisfaction and minimized prices connected with product loss.Raised Stockroom Room Application

Effective storage facility room application is a crucial variable in maximizing operations, and pallet Wrapping devices play a considerable function in accomplishing this goal. By safely Wrapping pallets, these equipments minimize the risk of product damage during storage and transportation, enabling extra effective piling and storage space techniques. Improved security means that pallets can be loaded higher without endangering safety and security, which optimizes upright space use. Furthermore, the constant Wrapping procedure assurances uniform dimensions, allowing better company and effective use of available room. This causes decreased aisle width requirements and enables even more product to be saved in the exact same area. In general, employing a pallet Wrapping machine improves space performance, adding to structured stockroom operations and enhanced efficiency.Often Asked Questions

What Kinds Of Products Can Be Wrapped Using a Pallet Wrapping Maker?

Different items can be covered utilizing a pallet Wrapping device, including boxes, pallets of food, commercial goods, and fragile items. The equipment accommodates varied sizes and shapes, making certain secure product packaging for effective transport and storage.

Just how much Does a Pallet Wrapping Device Usually Price?

The cost of a pallet more helpful hints Wrapping machine generally varies from $3,000 to $20,000, depending on abilities and functions. Elements such as automation level and brand online reputation can significantly affect the final price.Can Pallet Wrapping Machines Be Integrated With Existing Storage Facility Solutions?

Pallet Wrapping makers can frequently be integrated with existing stockroom systems, enhancing effectiveness (pallet wrapping machine repair). This combination enables streamlined operations, boosted supply management, and far better control with various other automated processes, ultimately enhancing overall storage facility functionalityWhat Is the Maintenance Requirement for Pallet Wrapping Machines?

The upkeep demands for pallet Wrapping equipments normally consist of routine assessments, lubrication of relocating components, and substitute of worn parts. Adhering to these practices guarantees peak efficiency and long life, lessening operational interruptions in stockroom settings.Exist Security Worries When Using Pallet Wrapping Machines?

Safety worries when making use of pallet Wrapping devices consist of prospective injuries from moving components, incorrect handling, and poor training. Guaranteeing proper safeguards, normal upkeep, and worker education can considerably minimize these threats in stockroom settings

Report this wiki page